Effective supply chain management is essential for maintaining competitiveness and satisfying customer expectations. However, the sheer volume and complexity of data generated throughout the supply chain can present obstacles. This is where business intelligence (BI) emerges as a transformative solution.

Through BI tools and technologies, you can derive actionable insights, recognize patterns, and make informed decisions across the entire supply chain lifecycle. By understanding how BI can revolutionize your approach to supply chain management, you'll be better equipped to navigate today's complex business landscape and stay ahead of the competition.

What is supply chain business intelligence?

Supply chain business intelligence refers to the use of data analysis tools and technologies to gain insights and optimize processes within the supply chain. It involves collecting, integrating, and analyzing data from various sources, including suppliers, manufacturers, distributors, retailers, and customers. By leveraging data-driven insights, organizations can unlock new opportunities for cost savings, operational efficiency, and sustainable growth.

Supply chain BI involves a wide range of activities, including:

Data integration: Gathering data from disparate sources such as enterprise resource planning (ERP) systems, customer relationship management (CRM) software, warehouse management systems (WMS), transportation management systems (TMS), and Internet of Things (IoT) devices.

Data analysis: Applying advanced types of analytics techniques such as data mining, machine learning, and predictive modeling to uncover patterns, trends, and correlations within the supply chain data.

Performance monitoring: Tracking key performance indicators (KPIs) and metrics related to supply chain activities, such as inventory levels, order fulfillment rates, transportation costs, and supplier performance.

Real-time visibility: Providing real-time visibility into the entire supply chain network, enabling stakeholders to monitor operations, identify bottlenecks, and respond quickly to changes or disruptions.

Decision support: Empowering decision-makers with actionable insights and recommendations to optimize inventory management, demand forecasting, production scheduling, procurement, logistics, and other supply chain processes.

Collaboration and communication: Facilitating collaboration and communication among supply chain partners through shared data insights, dashboards, and reports, fostering transparency, trust, and alignment.

The role of business intelligence in supply chain management

Business intelligence plays a crucial role in supply chain management by providing valuable insights for making decisions and enhancing overall performance. Here are some key aspects of BI's role in supply chain management:

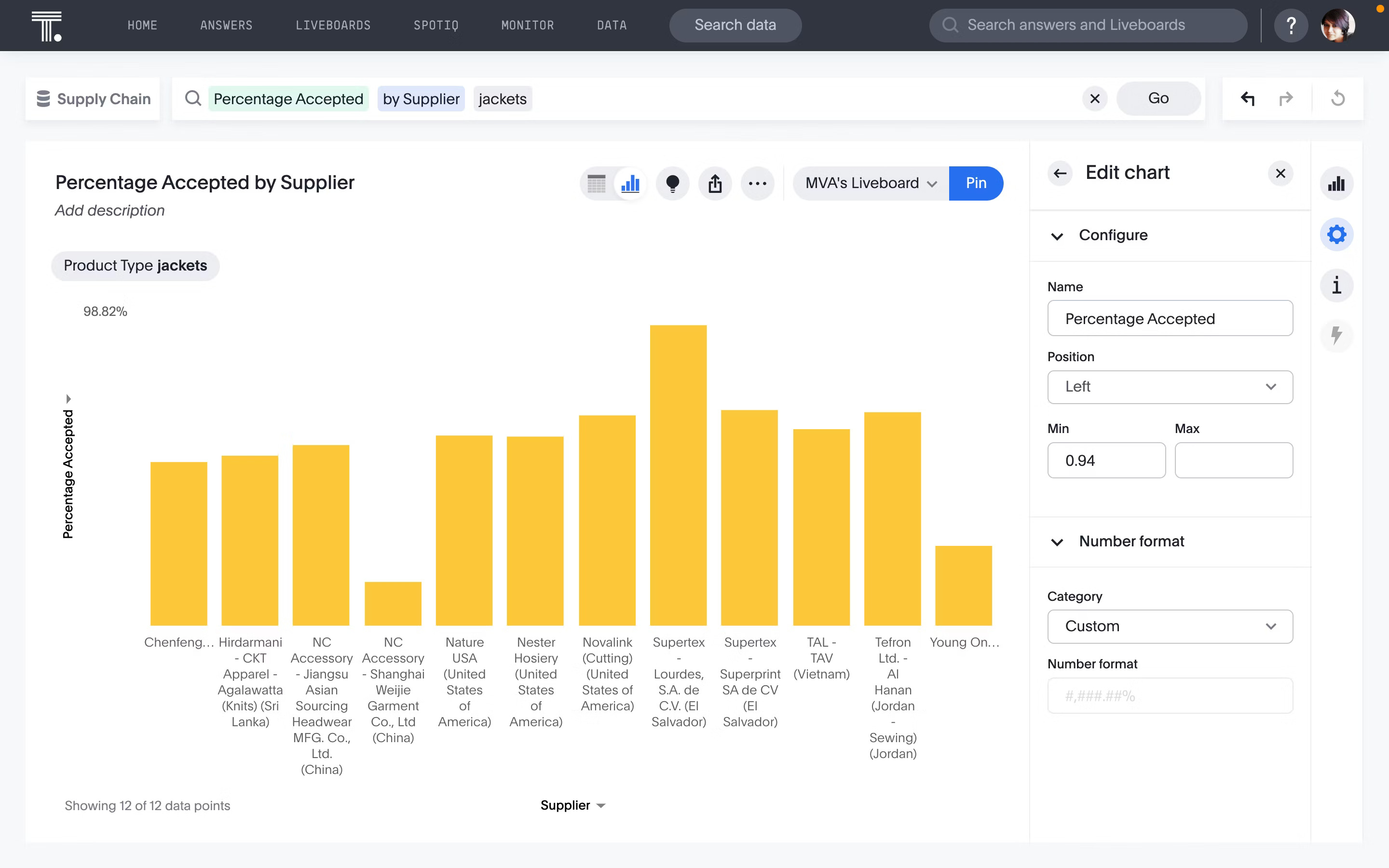

Data visualization: BI tools collect and integrate data from various sources across the supply chain, including suppliers, manufacturers, distributors, and customers. This data is then transformed into interactive data visualizations such as dashboards, reports, and graphs, making it easier for stakeholders to understand and analyze.

For instance, the visualization below provides you with an overview of which supplier's offering meets the buyer's requirements consistently.

Demand forecasting and planning: Utilizing historical data and predictive analytics, BI accurately forecasts demand. By analyzing factors like seasonal trends, market conditions, and customer behavior, organizations can optimize inventory levels, production schedules, and distribution strategies to meet customer demands while minimizing costs.

Supplier relationship management: BI facilitates better supplier relationship management by evaluating supplier performance based on factors like delivery times, quality standards, and pricing. This enables organizations to identify top-performing suppliers, negotiate better contracts, and mitigate risks associated with supplier disruptions.

Cost reduction and efficiency improvement: Identifying inefficiencies and bottlenecks in the supply chain, BI allows organizations to streamline processes, reduce lead times, and cut unnecessary costs. By optimizing routes, consolidating shipments, and improving resource allocation, organizations achieve significant cost savings and enhance overall efficiency.

Risk management: BI helps in identifying and mitigating risks in the supply chain, such as disruptions due to natural disasters, geopolitical events, or supplier failures. By analyzing historical data and scenario modeling, organizations can develop contingency plans, diversify their supplier base, and enhance supply chain resilience.

Real-life examples of BI in supply chain

1. OrderPay

OrderPay is a London-based hospitality and restaurant payment solution trusted by over 2,600 businesses in the UK. Facing challenges like rising costs and staff shortages, OrderPay's clients needed detailed insights into their performance and customer behavior to make better decisions. To meet this need, Elisa Morariu, Data Analytics Manager of OrderPay, looked for a self-service analytics solution.

OrderPay adopted ThoughtSpot across the company, enabling teams in Sales, Marketing, Product, Customer Support, and Operations to access valuable data. Today, more than 70% of the company's staff regularly use the system to make smarter choices and drive growth.

OrderPay's top Liveboards are mainly for keeping an eye on sales and customer performance. By connecting these two data sources in ThoughtSpot, OrderPay is now able to compare expected to actual performance, which helps the company support underperforming venue operators.

2. Amazon

Amazon utilizes BI to streamline operations and meet customer demands efficiently. Through BI, Amazon collects data from diverse sources, such as customer orders, browsing history, and social media interactions, to forecast demand accurately. Advanced analytics and machine learning algorithms analyze this data to predict future trends, enabling Amazon to optimize inventory levels in its fulfillment centers. By dynamically adjusting inventory, Amazon minimizes holding costs while ensuring products are available when customers need them. Furthermore, Amazon utilizes BI to optimize its logistics network, determining the most efficient routes for product delivery based on data on transportation costs, delivery times, and carrier performance.

3. Walmart

With a revenue of over $570 billion, Walmart continues to rank number one on Fortune’s Global 500 list and is constantly striving to improve its supply chain management system.

Walmart's strategy revolves around leveraging business intelligence to enhance efficiency and collaboration throughout its network. BI plays a crucial role in facilitating collaboration with suppliers, as Walmart shares sales data and demand forecasts to enable suppliers to adjust production schedules accordingly. Additionally, BI aids Walmart in optimizing inventory management by analyzing historical sales data, seasonal trends, and promotional activities to ensure optimal replenishment and minimize excess stock.

Driving supply chain success with data-driven insights

The integration of business intelligence into supply chain management has become increasingly vital for navigating the complexities of modern business environments. By leveraging data analytics and visualization tools, organizations can derive invaluable insights, leading to smarter decision-making and enhanced performance across the supply chain lifecycle.

ThoughtSpot stands as an innovative leader in business intelligence, offering a modern, AI-powered platform trusted by top-tier companies such as Nike, OrderPay, Flyer, and many more.

Streamline your supply chain operations with data-driven insights. Schedule a free demo with ThoughtSpot today.