If you sell products, you know understanding where your inventory is, who wants to buy it, and where it needs to go is essential to your business’s success. That’s why inventory optimization is an important use case for business analytics, and one of the most important (and persistent) trends in data analytics.

Inventory management should be a key part of any business's supply chain management strategy, especially during times of uncertainty. In this post, we will be exploring 6 techniques which businesses can employ to successfully optimize their inventories, and in doing so, build more sustainable, profitable organizations.

What is inventory optimization?

Inventory optimization is the process of managing inventory levels across a company's supply chain to reduce costs, improve customer service, and maximize profits.

By utilizing effective strategies for inventory optimization, you can ensure the best possible return on investment, save money by reducing unneeded stockpiles and improve customer service levels by having products available when customers need them. Without proper inventory management, however, your business could experience a range of setbacks from loss of revenue due to stockout costs, to larger costs associated with excess inventory that sits idle on shelves. Now let's understand the top techniques that businesses use to optimize their inventories.

Technique 1: ABC Analysis

ABC analysis is one of the most commonly used methods for inventory optimization. ABC analysis is a method for categorizing items in terms of their value to a business; it divides all items into three categories, A, B, and C. Items in category A are deemed the most important and valuable while items in category C are least important. This enables businesses to prioritize inventory levels and ensure they are stocking the right items, in the right quantities, based on what will deliver the most value to their customers and their organization.

How to conduct an ABC Analysis

1. Gather data

The first step is to gather historical data about each item in inventory, such as sales history, purchase price, and usage rate/frequency. With this historical data, you can determine which products should fall into each of the ABC categories.

2. Assign a value to each item

Once you have gathered your data, assign a weight to each item based on its importance. This will help you categorize items into A, B, and C based on the overall value or importance.

3. Categorize items

After assigning values to items, it is time to categorize them into A, B and C categories. Generally, items categorized as A will be the most important and valuable items to the business; those categorized as C will be the least important and valuable.

4. Adjust inventory levels

Once you have categorized your items into A, B and C, it is time to adjust inventory levels to ensure they match. Items in the A category should be prioritized, and appropriate stock levels should be maintained; items in the B and C categories can then be adjusted according to their importance.

Benefits of ABC Analysis

ABC analysis provides a number of benefits to businesses, specifically helping them prioritize their inventory levels, reducing overstocking and under-stocking of products, reducing lead times and increasing efficiency in the supply chain, and allowing for improved customer service. Additionally, ABC analysis can help reduce costs associated with inventory management by ensuring the right items are being stocked in the right quantities. By optimizing their inventory levels, businesses can improve their overall profitability and remain competitive in their industry.

Technique 2: Demand Forecasting

Demand forecasting is another technique companies can use to help optimize their inventory. Demand forecasting is the process of predicting customer demand for a product or service. It's an important tool used by businesses to develop successful strategies and plans, as it helps them anticipate their customer's needs while also reducing inventory costs. Demand forecasts are based on historical proprietary data, often relying on sales analytics to track sales over time, marketing analytics to understand customers, financial analytics to determine impact of different demand scenarios, and more, along with any relevant external factors such as economic conditions in different markets. By using this data, companies can make more accurate predictions about what their customers may need in the future and plan accordingly. This allows them to adjust prices and offerings so that they remain competitive in the market.

See how Canadian Tire was able to grow sales 20% despite 40% of stores closing during the pandemic by forecasting demand with ThoughtSpot.

Different methods for Demand Forecasting

There are several methods used to create demand forecasts, each of which can provide valuable insights into customer needs. The three most common approaches include time series analysis, regression analysis, and causal models.

Time series analysis looks at past trends in sales or consumption data to predict future trends. It involves using data where time is the independent variable, and accounts for seasonal factors such as holidays or changes in the economy that could affect demand for a product or service over that given period of time. Once this information is compiled, it can be used to forecast demand for future periods.

Regression analysis uses mathematical equations and statistical models to predict how changes in independent variables will affect demand. It can be used to analyze the relationship between two or more variables, such as price and quantity demanded, and make assumptions on how changing one variable may impact the other. This approach is particularly useful when multiple independent factors could influence customer demand, such as economic conditions or product availability.

Causal models rely on identifying a cause-and-effect relationship between two or more variables. They use mathematical formulas and statistical modeling techniques to determine how changes in one variable will impact the other, which helps businesses understand the key drivers of customer demand.

Benefits of Demand Forecasting

The benefits of demand forecasting are numerous. It enables businesses to anticipate customer demand for products, reducing the risk of overstocking and understocking. It can also allow companies to plan their supply chain operations more effectively, increasing efficiency and reducing lead times. Finally, it helps businesses stay ahead of the competition by enabling them to anticipate future market trends.

Technique 3: Safety Stock Management

Safety stock is a type of inventory that is maintained to ensure businesses can meet customer demand during peak periods. Think wrapping paper during the holidays, fuel at a gas station, or candy in American stores before Halloween. It helps to minimize the risk of stockouts and other inventory-related issues, keeping customers happy and businesses don’t miss out on sales.

How to calculate Safety Stock

Calculating safety stock involves estimating the average daily demand for a product, the lead time needed to restock, and the acceptable service level of stock availability.

To calculate safety stock, you need to know three pieces of information: your desired service level, your average lead time, and your average demand during lead time (ADLT). The formula for calculating safety stock is “service level (in decimal form) x ADLT x standard deviation of demand during lead time."

For example, if your desired service level is 95%, your ADLT is 10 days, and the standard deviation of demand during lead time is 5 units per day, then the safety stock is 47.5 (0.95 x 10 x 5). This means that at all times you should maintain a minimum inventory level of 47.5 units to meet customer demand when delays occur.

One mistake you don’t want to make however: Safety stock should not be confused with reorder point, which involves calculating the amount of inventory needed to trigger an order for more goods. A reorder point considers only the average daily demand during the lead time (ADLT), and does not take into account spikes in orders or other potential delays. Additionally, safety stock does not replace just-in-time (JIT) inventory management, where goods are ordered only as needed.

Benefits of Safety Stock Management

Efficient management of safety stock can enhance customer service levels as companies can better forecast customer demand and manage inventory more accurately, resulting in fewer order fulfillment delays. This translates to higher customer satisfaction as orders are fulfilled promptly and with greater precision.

Additionally, safety stock management aids companies in streamlining their supply chain operations and ensuring timely and appropriate delivery of products in the correct quantities. Safety stock management also provides companies with a cushion for potential shipping or receiving delays, as well as fluctuations in demand due to seasonal or unexpected events. Consequently, businesses benefit from increased stability and confidence in their preparedness for any unforeseen changes, which can lead to reduced lead times, enhanced customer loyalty, improved efficiency, and lower inventory costs.

Technique 4: SKU Rationalization

Have you ever walked into a store and thought “what don’t they sell here?” Too many products can actually hinder an organization’s ability to manage inventory. SKU rationalization is a type of inventory management system where businesses reduce the number of stock-keeping units (SKUs) they carry. This helps to reduce costs associated with storage, increase efficiency in ordering and fulfillment, and optimize product selection.

How to Conduct SKU Rationalization

To start the process of SKU rationalization, companies must first evaluate their current product line. This can include researching sales data and customer feedback to determine which products are most popular, as well as assessing the cost of producing and marketing each SKU. This can be done by data teams, or by merchandising teams if they’re empowered with self-service analytics.

Once the analysis is complete, companies can then decide which SKUs should be deleted, modified or kept in the product line. When deciding which SKUs to keep, companies should consider factors such as customer preference and profitability.

For example, a company may decide to keep a certain SKU if it has high customer satisfaction ratings despite low sales numbers; this indicates that customers still value the product and are willing to pay for it. On the other hand, if a SKU has low customer satisfaction ratings and low sales numbers, then it may be better for the company to delete or modify the product line instead of keeping it as-is.

By conducting regular SKU rationalization, companies can ensure that their product line is up-to-date and relevant to their customers.

Benefits of SKU Rationalization

SKU rationalization offers helps businesses reduce costs associated with storage and inventory management, better manage their product selection, ensure they are offering customers the products they need, and increase efficiency in ordering and fulfillment, allowing businesses to move more quickly when responding to customer demand.

Technique 5: Just-in-Time Inventory (JIT)

Just-in-time inventory, or JIT, is a type of inventory management system where products are ordered and delivered just before they are needed. This reduces the need for large amounts of inventory to be stored onsite, reducing costs associated with storage and ensuring freshness of products.

How to implement Just-in-Time Inventory

To begin implementing just-in-time (JIT) inventory management, companies must first assess their current inventory management process. This includes evaluating current procurement and stocking practices to identify where improvements can be made in the existing system. By assessing the current process, companies can identify any issues that might be preventing them from achieving maximum efficiency and cost savings. Having a streamlined procurement analytics and stocking system is essential for JIT inventory management to work.

Once you’ve determined your processes can support a JIT approach to inventory management, the next step is to develop a strategy for implementation. This includes mapping out the production process and identifying which components are necessary for each step. This allows companies to better understand their inventory needs and plan accordingly. Automating inventory planning provides massive value during this phase, as this will make it easier to manage orders and track stock levels.

Once the strategy is in place, companies can begin taking steps to optimize their inventory process. This includes determining what type of stock should be kept on hand and how much should be ordered at any given time. Companies must also consider the lead time for each component in order to ensure that they can meet their production deadlines without disruption. Additionally, companies should measure and track inventory levels to ensure that they are using optimal amounts of stock and avoiding unnecessary costs associated with excess inventory.

Benefits of Just-in-Time Inventory

Just-in Time (JIT) inventory management offers a number of benefits to businesses. It reduces inventory levels, reducing costs associated with inventory management. Businesses can also better stay ahead and respond to customer demand, boosting customer satisfaction. Lastly, it helps companies maintain their competitive advantage by ensuring their products are always in stock. Overall, JIT allows businesses to have better control over their supply chain, increasing efficiency and reducing lead times.

Technique 6: Inventory Automation

Inventory automation is a type of inventory management system where businesses use software and technology to automate the process of tracking, ordering, and managing their inventory. This helps businesses reduce manual labor while increasing accuracy and efficiency in their operations.

How to use ThoughtSpot for Inventory Automation

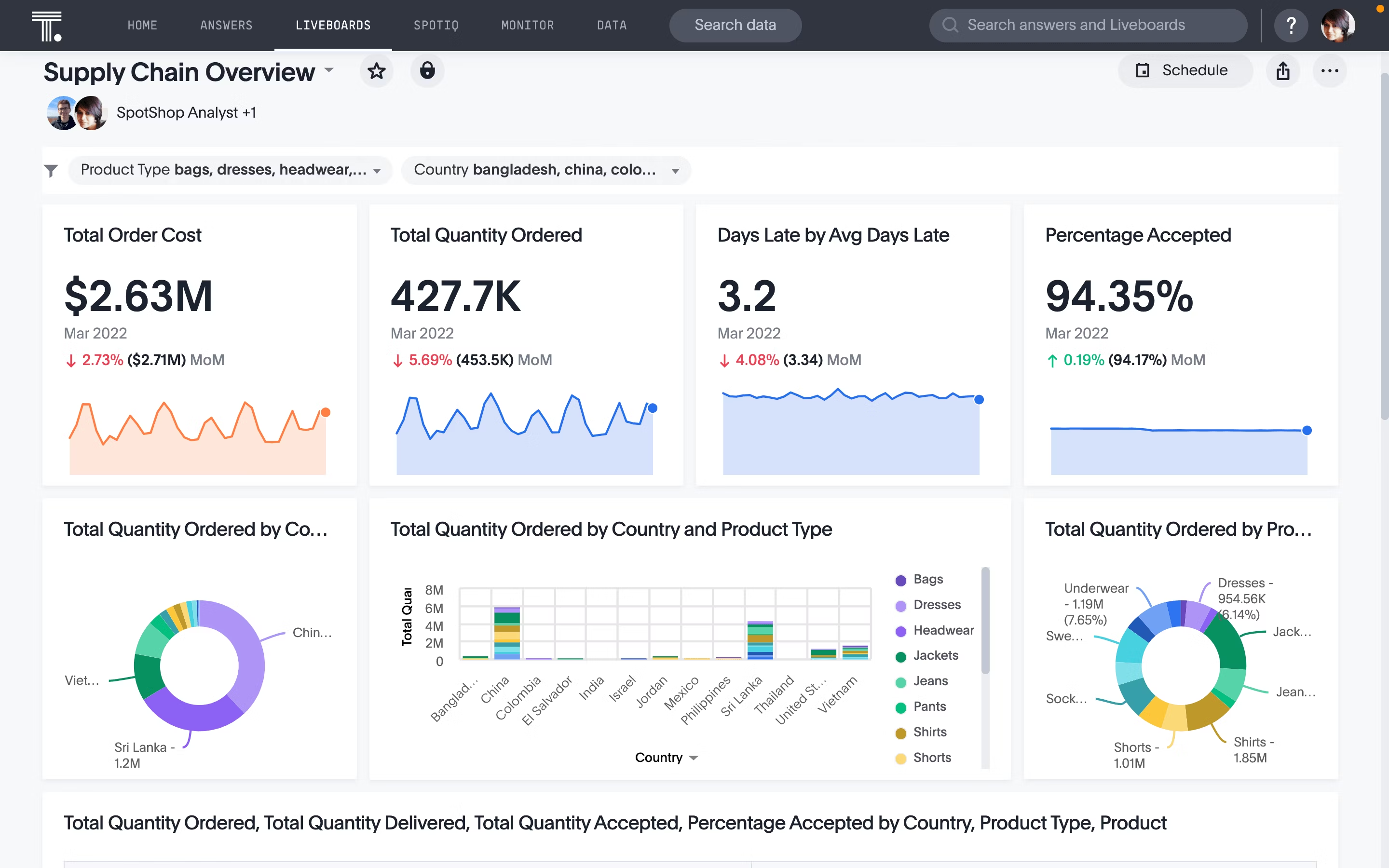

ThoughtSpot offers a comprehensive inventory automation solution that makes the process of managing and tracking inventory simpler and more efficient. With ThoughtSpot, you can easily keep track of what products or services are in stock and quickly generate reports to see where you have shortages or overstock. This helps reduce costs associated with manual counting, reordering, and restocking.

ThoughtSpot offers a range of features to make inventory automation easier. ThoughtSpot offers an intuitive business intelligence experience, anyone in your organization can create a data visualization to view stock levels, sales trends, and customer demand in real-time from any device, keeping you informed of all the details that go into maintaining balanced inventory levels.

In addition to viewing current inventory levels, ThoughtSpot also provides AI-Powered analytics to help you anticipate future demands and plan accordingly. You can set data-driven alerts that notify you when stock is running low or sales are increasing, so you can adjust your ordering process quickly and accurately.

Benefits of Inventory Automation

Inventory automation offers several benefits to businesses. It reduces the need for manual labor, increasing efficiency in their operations; it provides real-time visibility into inventory levels and customer demand, allowing businesses to better optimize their ordering and stocking processes; and it helps reduce costs associated with inventory management. Additionally, using inventory automation can help businesses remain competitive in their industry.

Start optimizing your inventory with ease

Inventory optimization is a crucial part of any business’s success. Utilizing the 6 techniques provided in this post can help you make an informed decision as to how to manage your company's inventory and optimize it according to the type of products or services that are offered. These strategies can help you better understand customer behavior and ensure that products are bought in the right quantities at the right time. When applying these strategies it is important to consider how they will affect the overall cost of your resources and keep track of sales forecasts. Implementing one or more of these strategies can lead to improved operations processes and bottom-line performance. With ThoughtSpot, you have access to analyst-level self-service reporting capabilities from a single platform meaning there’s no need for an expensive IT overhaul or retraining. Sign up now for a free trial with ThoughtSpot and see how their inventory optimization solution can set you up for success.